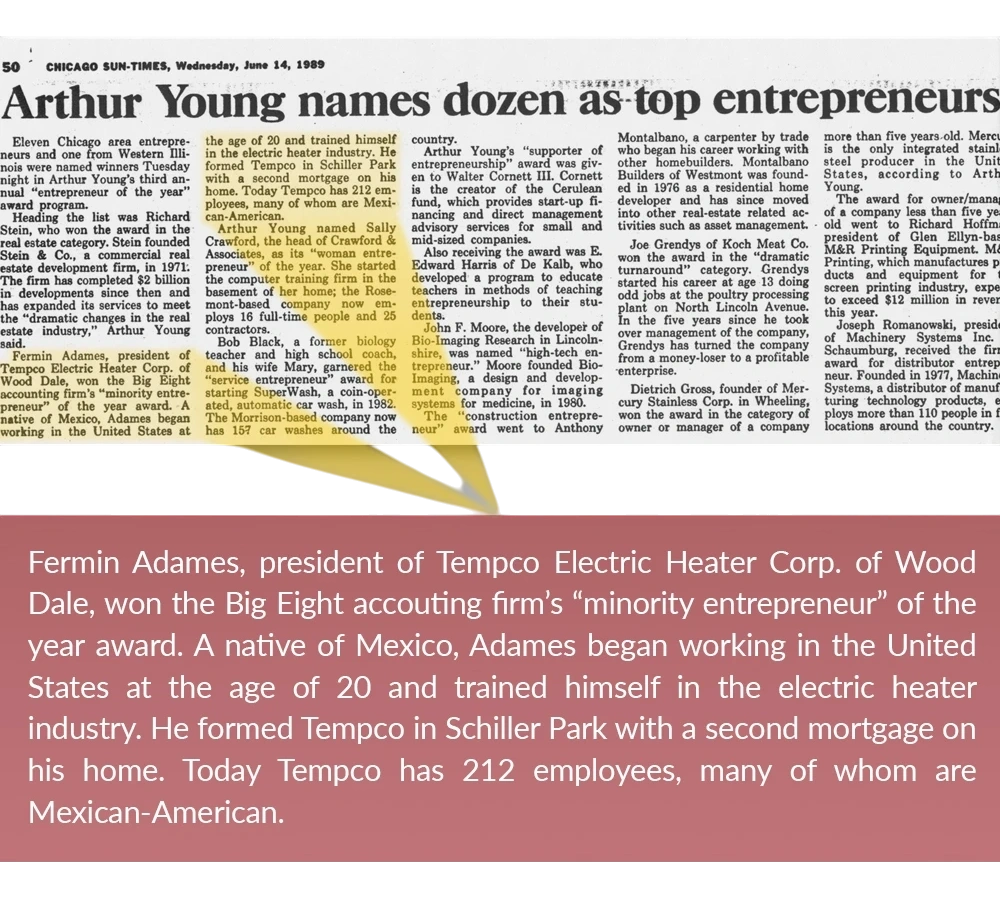

When my father, Fermin Adames Sr., founded Tempco in 1972 his intent was to offer the best products and customer service in the industry. He worked tirelessly towards that goal, knowing it would take a continual day-to-day effort. That business philosophy has fueled Tempco’s growth from three employees in a manufacturing space of approximately 1500 square feet to over 400 employees today occupying 174,000 square feet of manufacturing space.

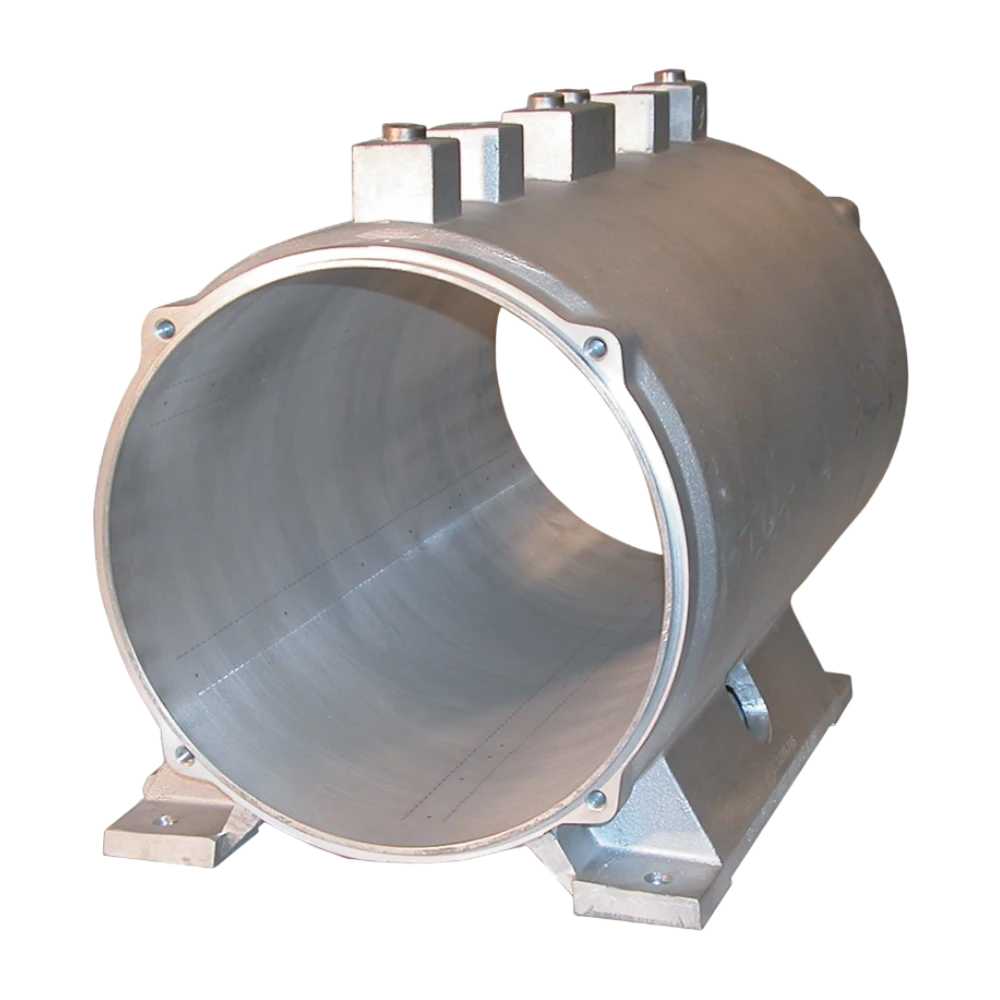

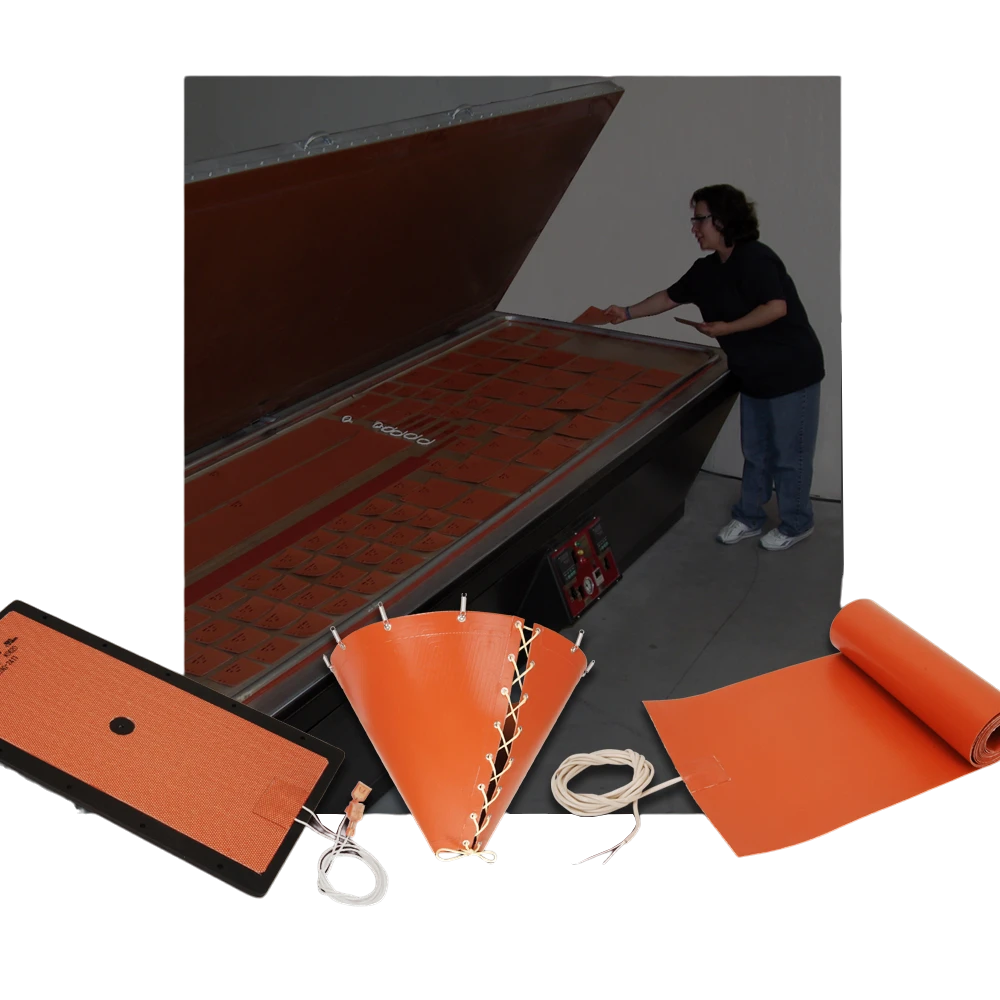

Our ISO 9001:2015 Certification, modern CNC machine shop & CNC sheet metal department, Aluminum and Bronze Foundry, Wood Pattern Shop, UL 508A Certified Panel Shop along with all of our fabrication and assembly areas guarantee quality, custom-manufactured, American-made products delivered to our customers on time.

We look forward to continuing to serve our customers for many years to come.

Fermin Alan Adames

President

Company Timeline

Our History

Over 50 Years of Excellence

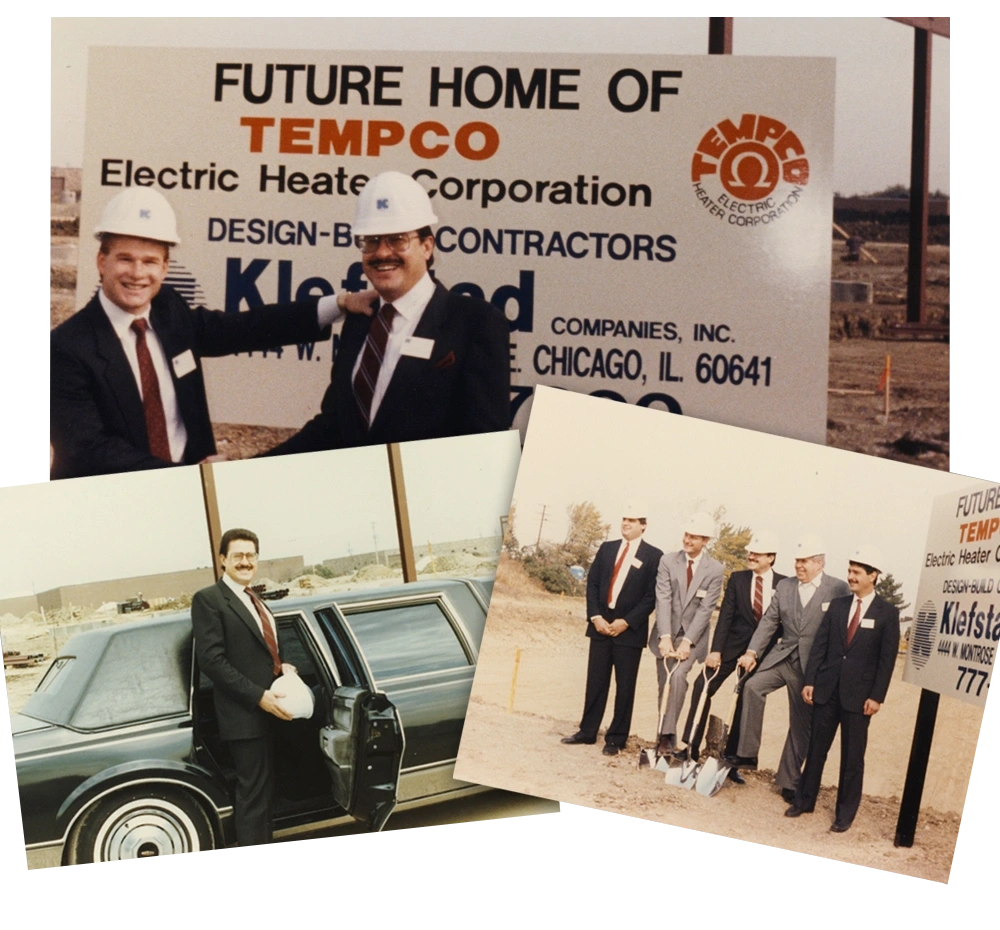

How we got started

Tempco was founded to manufacture electric heating elements for a wide range of industrial, commercial, scientific and medical applications. Mr. Adames’ leadership, ingenuity, dedication to hard work and focus on high-quality products and service have led Tempco to become one of the best electric heating element manufacturers in the world.

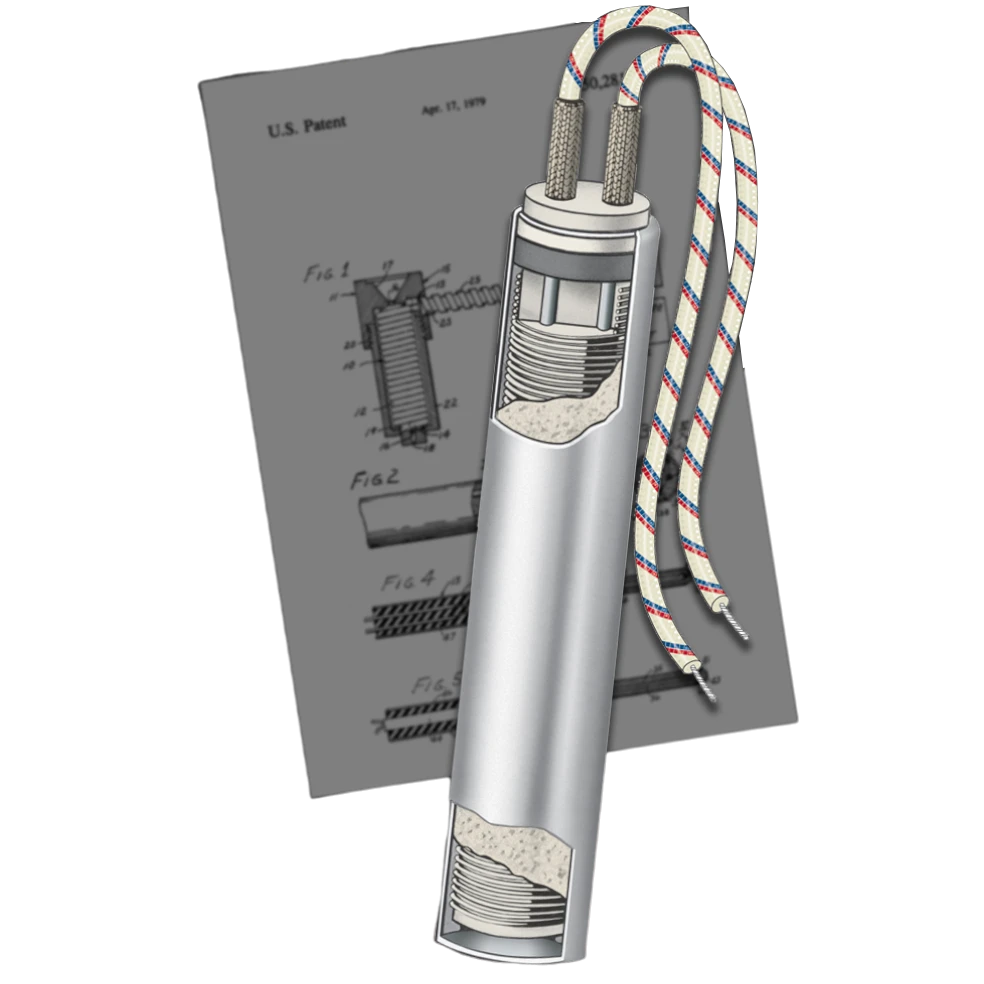

During the Company’s early years, Mr. Adames made a commitment to an ongoing program for the research and development of new and improved products. This foresight has contributed to the broadening of our product lines on a regular basis. As a result, Tempco has consistently met the needs of the diversified industries in which various types of heating elements are used.

Tempco Today

Today we manufacture approximately thirty different types of electric heating elements and temperature sensors with hundreds of design variations. Some of our products were original developments in the industry for which Tempco holds patents. Many of our manufactured products are UL certified and CSA recognized. In addition to meeting our own rigorous quality standards, Tempco is an ISO:9001 certified company.

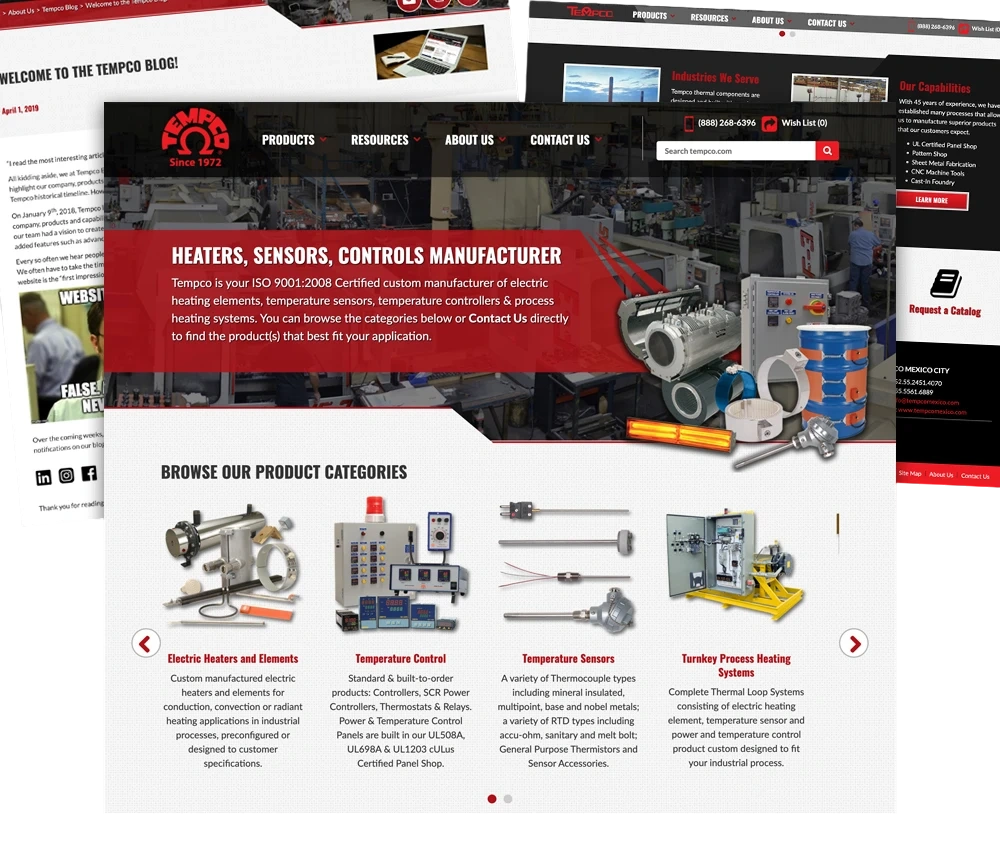

Over the years Tempco’s growth has necessitated moves to larger facilities several times. Today we occupy our second and third custom-built offices and manufacturing facilities located in Wood Dale, Illinois. Our labor force consists of approximately 500 employees, and our annual sales are in the millions.

An American Institution

Tempco is proud to produce American made and manufactured products. Our products are sold both nationally and internationally through a network of sales representatives and distributors and through our own distribution center located in Mexico City, Mexico. We serve original equipment manufacturers (OEMs) and end users alike. Our customers can be found in many industries such as plastics, rubber, packaging, medical, transportation, additive manufacturing, energy, and food service industries. We also service numerous industries where our products are used for heat processing.