Click or tap image to expand

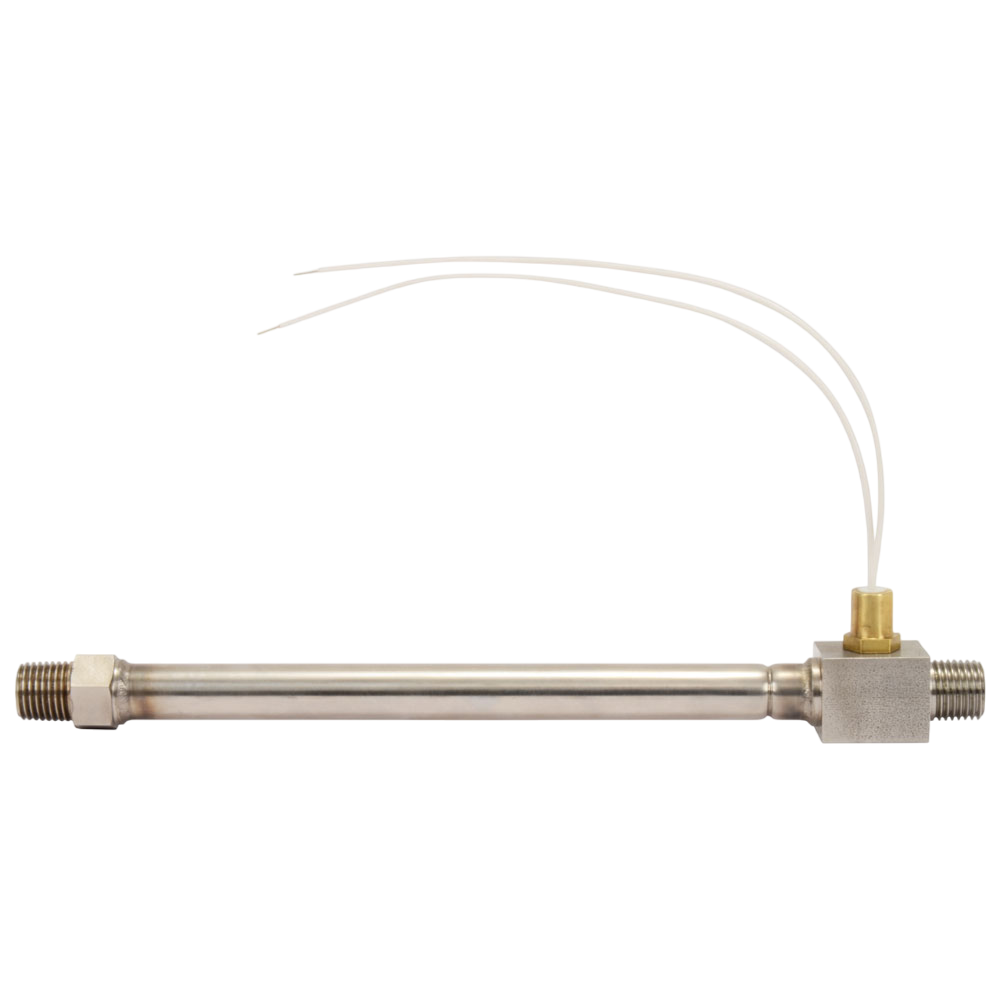

In-Line Forced Air Heaters

Typical Applications

- Laminating

- Plastic Welding

- Drying

- Soldering

- Baking

- Preheating and Metalworking

- Shrink Fitting

- Packaging

- Heat Shrinking

- Sterilization

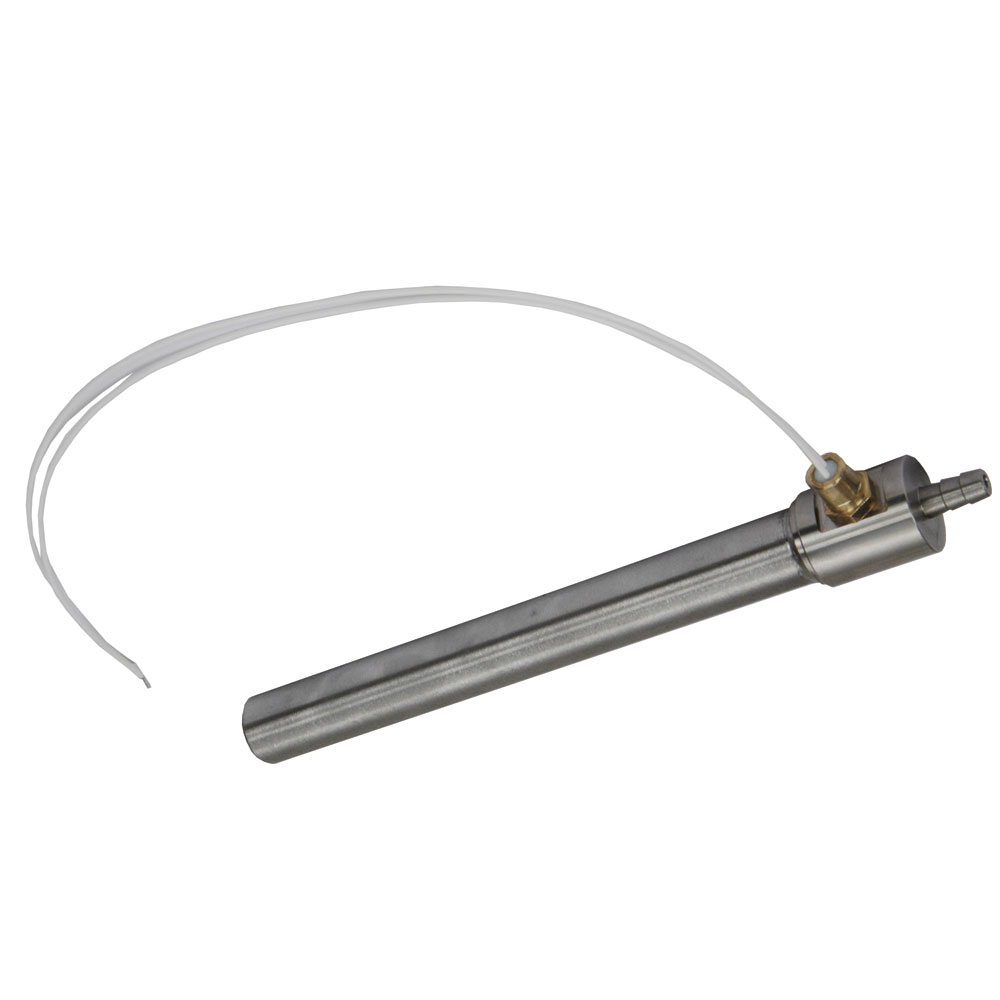

LDA In-line forced air heaters

Design Features:

- Stainless Steel fitting is heli- arc welded at the air outlet.

- Alloy 304 stainless steel tubing is used to provide high temperature strength and resistance to oxidation up to outlet temperature of 1000°F (538°C).

Inlet air or gas temperature up to 250°F (121°C). - Stainless Steel fitting is heli-arc welded at the air inlet.

- Standard termination is 10″ (254 mm) long, Teflon® insulated lead wires exiting through a potting adapter.

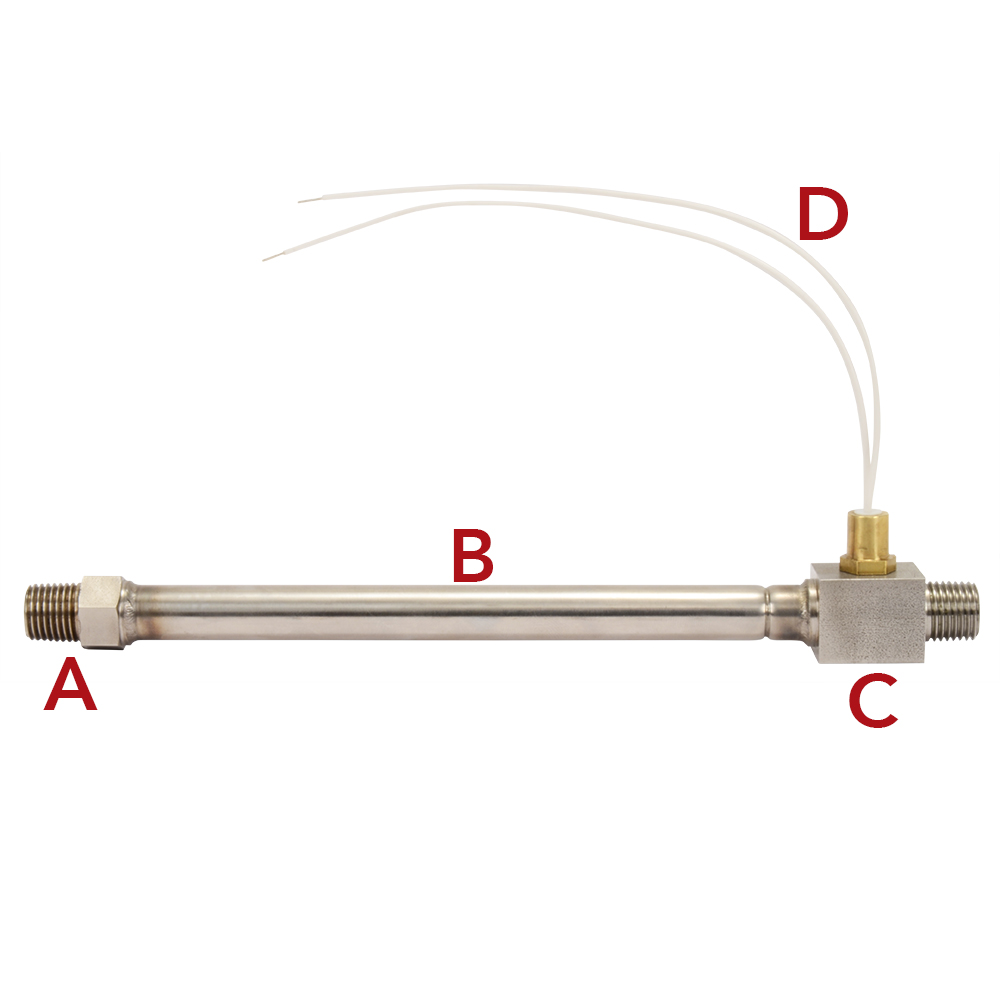

Heater Description

A

Stainless Steel fitting is heli- arc welde at the air outlet.

B

Alloy 304 stainless steel tubing is used to provide high temperature strength and resistance to oxidation up to outlet temperature of 1000°F (538°C). Inlet air or gas temperature up to 250°F (121°C).

C

Stainless Steel fitting is heli-arc welded at the air inlet.

D

Standard termination is 10″ (254 mm) long, Teflon® insulated lead wires exiting through a potting adapter.

Heater Specifications

| Heater Diameter (in) | Maximum Amperage | Cross Sectional Flow Area (in2) | Maximum SCFM (ft2) | Maximum Wattage/Linear Inch Of Heated Length |

|---|---|---|---|---|

| 3/8 | 6 | .030 | 8 | 200 |

| 1/2 | 8 | .040 | 10 | 250 |

| 3/4 | 15 | .120 | 20 | 500 |

| Diameter | “A” | Watts | Volts | Connection | Part Number | |

|---|---|---|---|---|---|---|

| in | (mm) | |||||

| 0.5 | 51⁄2 | 139.7 | 400 | 120 | 3 Pins Male Insert | LDA00194 |

| 0.5 | 51⁄2 | 139.7 | 400 | 240 | 3 Pins Male Insert | LDA00196 |

| 0.5 | 51⁄2 | 139.7 | 600 | 120 | 3 Pins Male Insert | LDA00197 |

| 0.5 | 51⁄2 | 139.7 | 600 | 240 | 3 Pins Male Insert | LDA00198 |

| 0.5 | 51⁄2 | 139.7 | 400 | 120 | 36″ Leads | LDA00195 |

| 0.5 | 51⁄2 | 139.7 | 400 | 240 | 36″ Leads | LDA00199 |

| 0.5 | 51⁄2 | 139.7 | 600 | 120 | 36″ Leads | LDA00200 |

| 0.5 | 51⁄2 | 139.7 | 600 | 240 | 36″ Leads | LDA00201 |

Optional Features:

- Other wattages and voltages

- Other diameters or lengths

- 1/8″, 1/4″, and 3/8″ NPT male or female threads are available for the inlet and outlet fittings

- External MI cable thermocouple

- Other custom made fittings or flanges

- S/S cable or braid for lead wire protection

- SJO cord

Heater Selection

To ensure maximum heater life, heater wattage must be calculated so that it is suitable for the desired air flow. To calculate wattage, determine the air flow and temperature rise required. The following relationship can be used to determine the wattage.

| Wattage = | SCFM × Temperature Rise (°F) |

| 3 |

Table below shows the relationship between standard cubic feet per minute versus maximum watts per linear inch of heated length on different heater diameters.

| Maximum Watts per Linear Inch of Heated Length | ||||

|---|---|---|---|---|

| CFM | 3/8″ Dia. | 1/2″ Dia. | 5/8″ Dia. | 3/4″ Dia. |

| 2 | 80 | 80 | 100 | 120 |

| 4 | 100 | 100 | 100 | 120 |

| 6 | 150 | 150 | 150 | 150 |

| 8 | 200 | 200 | 200 | 200 |

| 10 | — | 250 | 250 | 250 |

| 15 | — | — | 375 | 375 |

| 20 | — | — | — | 500 |

Note: Air heaters must always have air flowing through them and must operate in a horizontal position to balance the internal resistance coil. Air Heaters can be made in any practical length. These sizes can be adapted with many types of fittings.

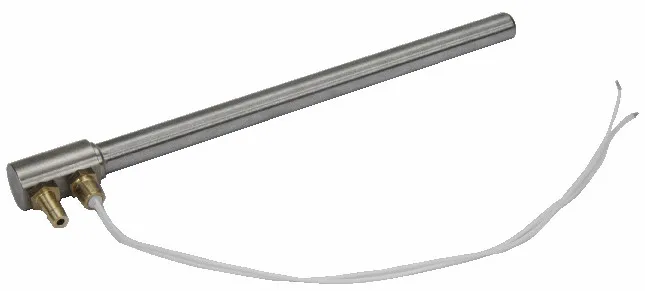

HAC In-line forced air process heaters

Design Features:

- Two standard sizes: 1/2″ diameter × 8″ long, 11/16″ diameter × 6″ long

- 304 Stainless Steel sheath

- 120 Volt only

- Exit air or gas temperature up to 1400°F (760°C)

- Inlet air or gas temperature up to 250°F (121°C)

- Ceramic coil support and insulator

- Three different terminations

- Customized termination, inlet, outlet, and wattage to customer specification available

Heater Construction

Daisy Wound Heating Element: This continuous wound heavy gauge high temperature alloy wire is supported on a custom designed ceramic insulator. This unique coil design rapidly and efficiently removes heat from the resistor wire to achieve higher air/gas temperatures than conventional coil wound designs. The coil assembly is enclosed a in stainless steel housing for safety and durability. Termination can be customized to suit your specific application. Consult Tempco with your requirements.