Click or tap image to expand

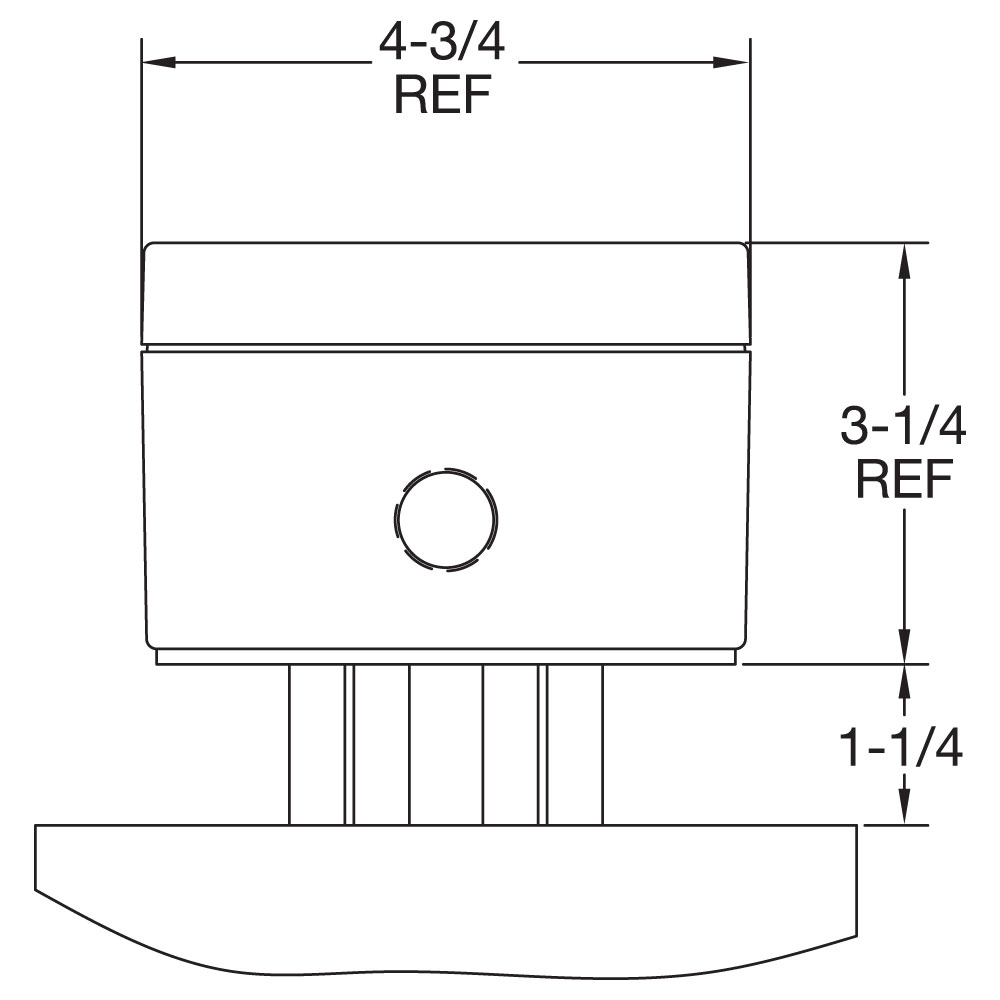

Cast-In Platen Die Heaters

Refine Results

(4 filters)Cast Materials

No options available for this section based on your selections

Aluminum

Material: Standard Aluminum 319 (Optional Aluminum 356 in Learn More)

Maximum Surface Temperature: 700°F (371°C)

Density (lb/in3): 0.101

Coefficient of Linear Thermal Expansion (in/in/°F × 10-6): 12.7 @ 68° – 572°F

Thermal Conductivity (BTU-in/hr-ft2-°F): 754

Aluminum

Material: Standard Aluminum 319 (Optional Aluminum 356 in Learn More)

Maximum Surface Temperature: 700°F (371°C)

Density (lb/in3): 0.101

Coefficient of Linear Thermal Expansion (in/in/°F × 10-6): 12.7 @ 68° – 572°F

Thermal Conductivity (BTU-in/hr-ft2-°F): 754

Material: Optional Aluminum 356

Maximum Surface Temperature: 750°F (399°C)

Density (lb/in3): 0.0968

Coefficient of Linear Thermal Expansion (in/in/°F × 10-6): 12.9 @ 68° – 572°F

Thermal Conductivity (BTU-in/hr-ft2-°F): 1160

| Material | Classification | Specific Heat Capacity (BTU/lb-°F) |

Melting Point °F |

|---|---|---|---|

| Aluminum 319 | Aluminum 319.0 | 0.23 |

960 – 1120 |

| Aluminum 356 | Aluminum 356.0 | 0.23 | 1030 – 1140 |

Scroll for more

| Casting Alloy | Aluminum | Copper | Silicone | Zinc | Lead | Iron | Tin | Other |

|---|---|---|---|---|---|---|---|---|

| Aluminum 319 | 85.8 – 91.58% | 3.0 – 4.0% | 5.50 – 6.50% | ≤ 1.0% | — | ≤ 1.0% | — | ≤1.7% |

| Aluminum 356 | 90.1 – 93.3 % | ≤0.25% | 6.50 – 7.50% | ≤0.35% | — | ≤0.60% | — | ≤1.125% |

Scroll for more

ADDITIONAL RESOURCES

Bronze

Material: Bronze

Maximum Surface Temperature: 1350°F (732°C)

Density (lb/in3): 0.272

Coefficient of Linear Thermal Expansion (in/in/°F × 10-6): 9 @ 68° – 572°F

Thermal Conductivity (BTU-in/hr-ft2-°F): 437

Bronze

Material: Bronze

Maximum Surface Temperature: 1350°F (732°C)

Density (lb/in3): 0.272

Coefficient of Linear Thermal Expansion (in/in/°F × 10-6): 9 @ 68° – 572°F

Thermal Conductivity (BTU-in/hr-ft2-°F): 437

| Material | Classification | Specific Heat Capacity (BTU/lb-°F) |

Melting Point °F |

|---|---|---|---|

| Bronze | UNS C95300 | 0.0896 |

1900 – 1913 |

Scroll for more

| Casting Alloy | Aluminum | Copper | Silicone | Zinc | Lead | Iron | Tin | Other |

|---|---|---|---|---|---|---|---|---|

| Bronze | 9.0 – 11.0% | ≥ 86.0% | — | — | — | 0.80 – 1.50% | — | ≤1% |

Scroll for more

ADDITIONAL RESOURCES

Electrical Terminations

No options available for this section based on your selections

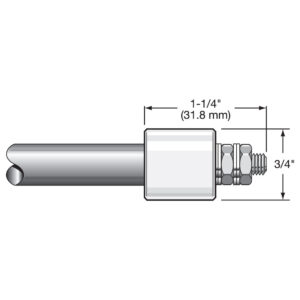

Type S: Heavy Duty Ceramic Insulators (Standard)

Standard unless otherwise specified. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

Type S: Heavy Duty Ceramic Insulators (Standard)

Standard unless otherwise specified. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

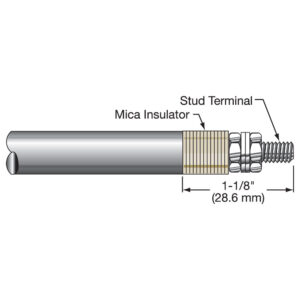

Type T: Mica Insulator

Mica insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

Type T: Mica Insulator

Mica insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

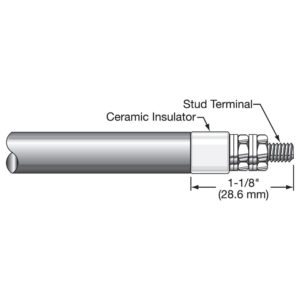

Type T7: Ceramic Insulator

Ceramic insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals

Type T7: Ceramic Insulator

Ceramic insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals

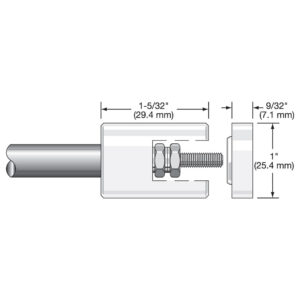

Type C4: Heavy Duty Ceramic Insulator with Terminal Cover

Heavy duty ceramic insulator with terminal cover. .315″ diameter heater has 10-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

Type C4: Heavy Duty Ceramic Insulator with Terminal Cover

Heavy duty ceramic insulator with terminal cover. .315″ diameter heater has 10-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

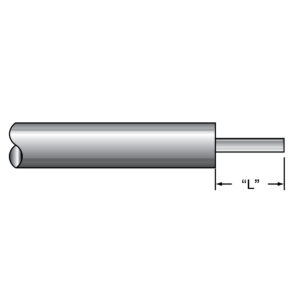

Type P: Plain Pin

Plain terminal pin. Specify Length “L.” Standard 1/2″ (12.7 mm) pin length.

Type P: Plain Pin

Plain terminal pin. Specify Length “L.” Standard 1/2″ (12.7 mm) pin length.

| Element Diameter | NominalPin Diameter | ||

|---|---|---|---|

| in | mm | in | mm |

| 0.26 | 6.6 | 0.091 | 2.3 |

| 0.315 | 8 | 0.1 | 2.5 |

| 0.43 | 10.9 | 0.12 | 3 |

Scroll for more

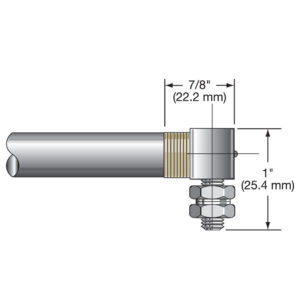

Type R: Mica Washers

Mica washers with 90° blockhead screw terminal with 10-32 screw threads. Available for .315″ and .430″ diameter heaters.

Type R: Mica Washers

Mica washers with 90° blockhead screw terminal with 10-32 screw threads. Available for .315″ and .430″ diameter heaters.

Type R2: Mica Washers with Lead Wire Connection

Mica washers with blockhead and through hole for lead wire connection. Eliminates the use of ring terminals. Available for .315″ and .430″ diameter heaters. Accepts 6-14 gauge wire.

Type R2: Mica Washers with Lead Wire Connection

Mica washers with blockhead and through hole for lead wire connection. Eliminates the use of ring terminals. Available for .315″ and .430″ diameter heaters. Accepts 6-14 gauge wire.

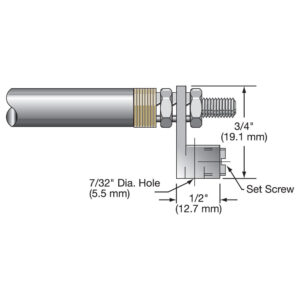

Type E: Right-Angle Lug

Right-angle lug welded to pin with mica washer insulators and 10-32 binding head screw. Available for .260″, .315″ and .430″ diameter heaters.

Type E: Right-Angle Lug

Right-angle lug welded to pin with mica washer insulators and 10-32 binding head screw. Available for .260″, .315″ and .430″ diameter heaters.

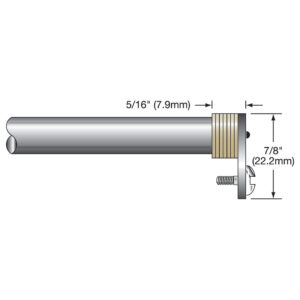

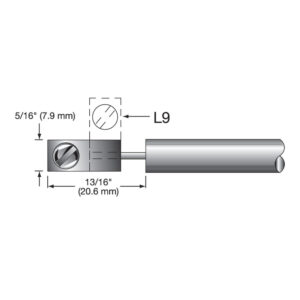

Type L and L9: Terminal Lug and Pin

Terminal lug spot welded to pin with 10-32 binding head screw. Available for .260″, .315″ and .430″ diameter heaters. Type L represents straight; Type L9 represents 90° to pin. Specify lug orientation.

Type L and L9: Terminal Lug and Pin

Terminal lug spot welded to pin with 10-32 binding head screw. Available for .260″, .315″ and .430″ diameter heaters. Type L represents straight; Type L9 represents 90° to pin. Specify lug orientation.

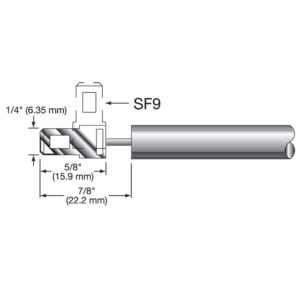

Type SF and SF9: Quick Disconnect Spade Tabs

Quick-disconnect spade tabs spot welded to pin. Available for .260″, .315″ and .430″ diameter heaters. Type SF represents straight. Type SF9 represents 90° to pin. Specify tab orientation.

Type SF and SF9: Quick Disconnect Spade Tabs

Quick-disconnect spade tabs spot welded to pin. Available for .260″, .315″ and .430″ diameter heaters. Type SF represents straight. Type SF9 represents 90° to pin. Specify tab orientation.

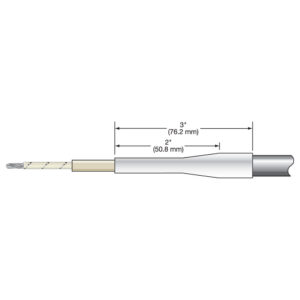

Type F: Flexible Lead

Flexible lead: insulated stranded wire crimped to cold pin. Crimp connection is insulated with fiberglass sleeving. Available for .260″, .315″ and .430″ diameter heaters. Wire insulation rated to 250°C, 450°C optional. Specify lead length.

Type F: Flexible Lead

Flexible lead: insulated stranded wire crimped to cold pin. Crimp connection is insulated with fiberglass sleeving. Available for .260″, .315″ and .430″ diameter heaters. Wire insulation rated to 250°C, 450°C optional. Specify lead length.

Type R1: Flexible Armor Cable

Flexible Armor Cable provides excellent protection to lead wires against abrasion and contaminants. Available for .260″, .315″ and .430″ diameter heaters. Specify cable length and lead length. Style may vary from depiction depending on heater diameter and cable diameter used.

Type R1: Flexible Armor Cable

Flexible Armor Cable provides excellent protection to lead wires against abrasion and contaminants. Available for .260″, .315″ and .430″ diameter heaters. Specify cable length and lead length. Style may vary from depiction depending on heater diameter and cable diameter used.

Type R1A: Stainless Steel Wire Overbraid

Stainless Steel Wire Overbraid provides flexibility and excellent protection to lead wires against abrasion. Available for .260″, .315″ and .430″ diameter heaters. Specify stainless steel wire overbraid length and lead length. Style may vary from depiction depending on heater diameter and braid diameter used.

Type R1A: Stainless Steel Wire Overbraid

Stainless Steel Wire Overbraid provides flexibility and excellent protection to lead wires against abrasion. Available for .260″, .315″ and .430″ diameter heaters. Specify stainless steel wire overbraid length and lead length. Style may vary from depiction depending on heater diameter and braid diameter used.

Type MR: Strain Relief and Lead Wire – Moisture Resistant

Moisture resistant shrink strain relief and lead wire with or without stainless steel overbraid. Available for .260″, .315″ and .430″ diameter heaters. Specify lead wire and overbraid length. Maximum operating temperature is 350°F (177°C).

Type MR: Strain Relief and Lead Wire – Moisture Resistant

Moisture resistant shrink strain relief and lead wire with or without stainless steel overbraid. Available for .260″, .315″ and .430″ diameter heaters. Specify lead wire and overbraid length. Maximum operating temperature is 350°F (177°C).

Type TS: Teflon® Sleeving over Lead Wire

Contamination seal shrink-down Teflon® sleeving over the heater and lead wire splice. Provides a good moisture resistant seal. Maximum operating temperature 500°F (260°C). Available for .260″, .315″ and .430″ and diameter heaters. Specify lead length.

Type TS: Teflon® Sleeving over Lead Wire

Contamination seal shrink-down Teflon® sleeving over the heater and lead wire splice. Provides a good moisture resistant seal. Maximum operating temperature 500°F (260°C). Available for .260″, .315″ and .430″ and diameter heaters. Specify lead length.

Type P1: Quick Disconnect Plug

Quick-disconnect plug, either mounted directly on casting or on elements ends offset a specified distance from casting. Rating: 16A-250VAC.

Type P1: Quick Disconnect Plug

Quick-disconnect plug, either mounted directly on casting or on elements ends offset a specified distance from casting. Rating: 16A-250VAC.

Termination Protection

No options available for this section based on your selections

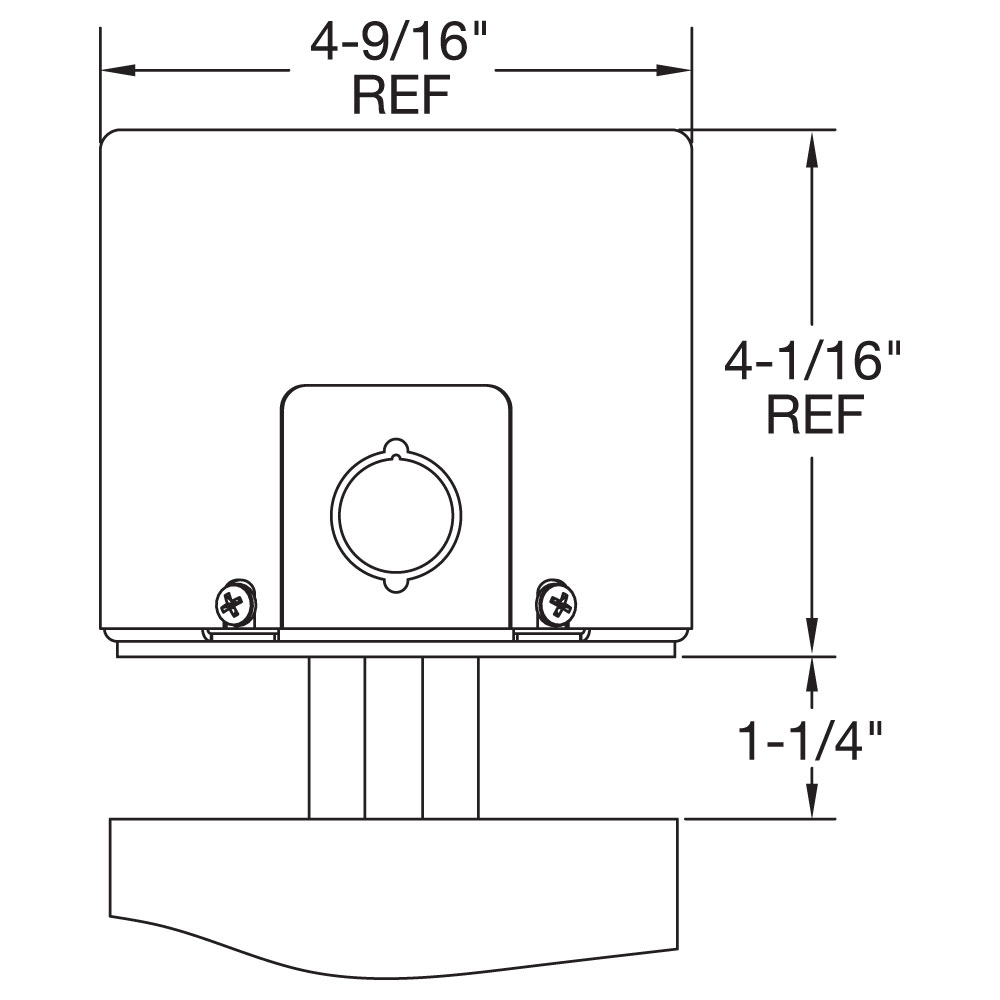

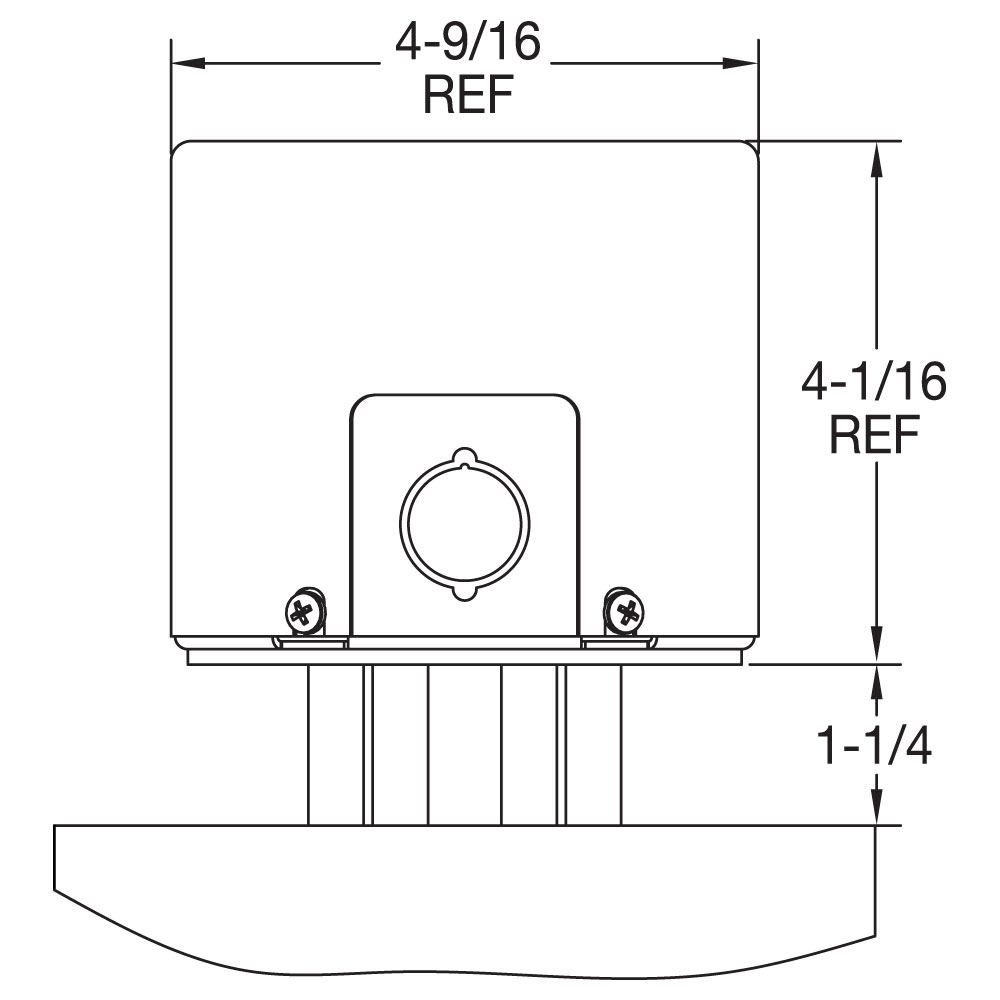

Type C2: Standard Terminal Box (on flat pad)

Type C2 is an individual terminal box for protecting the terminals on each Cast-In Band Heater half and on many other Cast-In Heater designs with one set of heater terminals. The C2 box design requires a flat pad on half-round castings or a flat surface on other casting designs for mounting. It is made from heavy gauge, rust-resistant sheet metal. The cover is removable for easy access to terminals. The box has two 7/8″ diameter knockouts opposite each other for standard 1/2″ BX connectors.

Type C2: Standard Terminal Box (on flat pad)

Type C2 is an individual terminal box for protecting the terminals on each Cast-In Band Heater half and on many other Cast-In Heater designs with one set of heater terminals. The C2 box design requires a flat pad on half-round castings or a flat surface on other casting designs for mounting. It is made from heavy gauge, rust-resistant sheet metal. The cover is removable for easy access to terminals. The box has two 7/8″ diameter knockouts opposite each other for standard 1/2″ BX connectors.

To simplify installation, Cast-In Heaters fitted with boxes can be factory pre-wired with high temperature lead wire that can be protected with armor cable. If one of these options is required, specify terminal box type, lead wire and cable length.

Satisfies NEMA 1 requirements.

Standard C2 box size: L = 4″ W = 2-1/2″ H = 2-1/8″

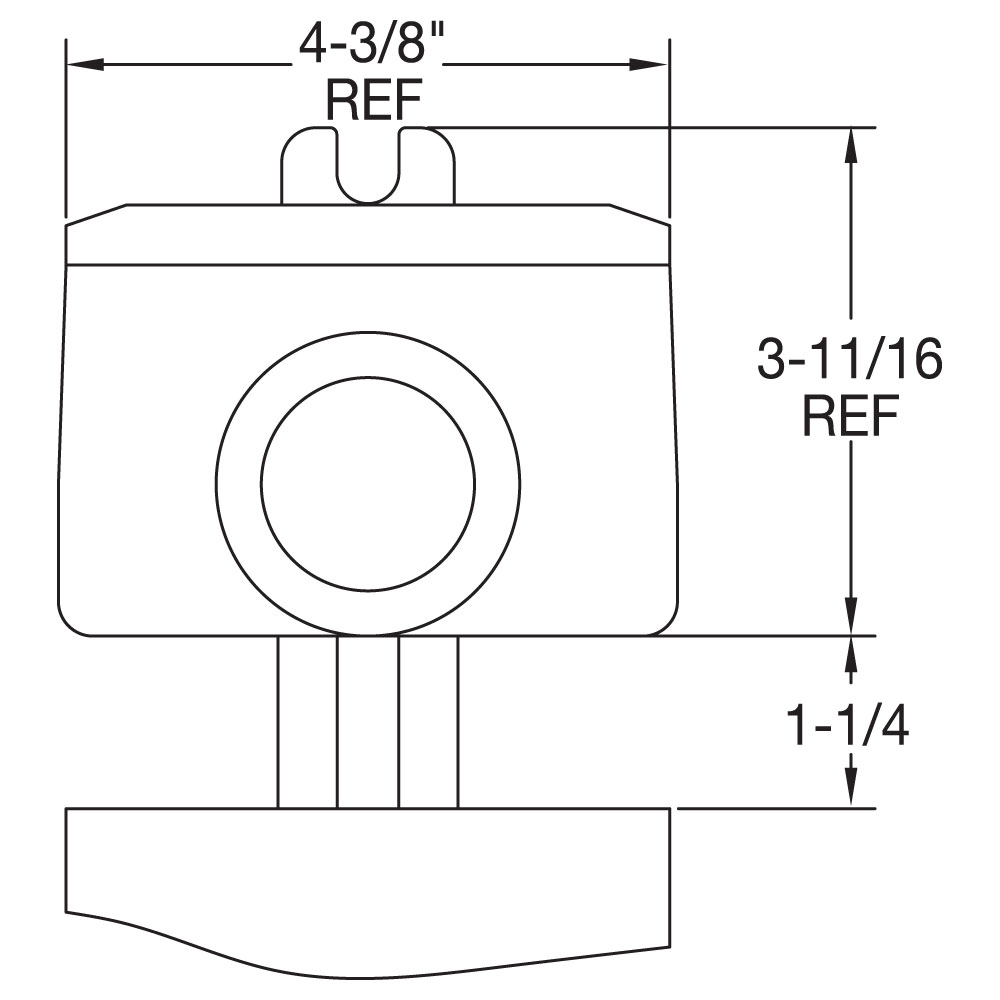

Type P2: Quick Disconnect Plug Assembly with Box

Quick-Disconnect Cup assemblies provide the simplest and safest means for applying power to any type of Cast-In Heater installation. The box extends over the screw terminals on both Cast-In Band Heater halves. The combination of prewired cup and box assembly, along with factory prewired high temperature lead wire protected with armor cable, eliminates live exposed heater terminals and electrical wiring, protecting employees from electrical shock and the possibility of electrical shorts due to exposed wiring.

Type P2: Quick Disconnect Plug Assembly with Box

Quick-Disconnect Cup assemblies provide the simplest and safest means for applying power to any type of Cast-In Heater installation. The box extends over the screw terminals on both Cast-In Band Heater halves. The combination of prewired cup and box assembly, along with factory prewired high temperature lead wire protected with armor cable, eliminates live exposed heater terminals and electrical wiring, protecting employees from electrical shock and the possibility of electrical shorts due to exposed wiring.

If prewired plugs are required, specify length of lead wire and cable.

Rated 250V maximum, 15 Amp maximum

Terminal Box Size varies with dimensions of casting.

Type EP: Explosion & Moisture Resistant Box

Cast iron explosion and moisture resistant boxes should be used in areas where the surrounding air may become contaminated with combustible gases or a high humidity level may exist. Installation requires one box per Cast-In Heater half and they are brazed to the tubular heater. The standard box has one 1/2″ NPT hub.

Type EP: Explosion & Moisture Resistant Box

Cast iron explosion and moisture resistant boxes should be used in areas where the surrounding air may become contaminated with combustible gases or a high humidity level may exist. Installation requires one box per Cast-In Heater half and they are brazed to the tubular heater. The standard box has one 1/2″ NPT hub.

Optional: Two hubs per box available. Cast-In Heater fitted with boxes can be factory prewired with high temperature lead wire, protected with special armor cable. If either of these options is required, please specify the following:

- Number of hubs

- Cable type

- Lead wire length

- Cable length

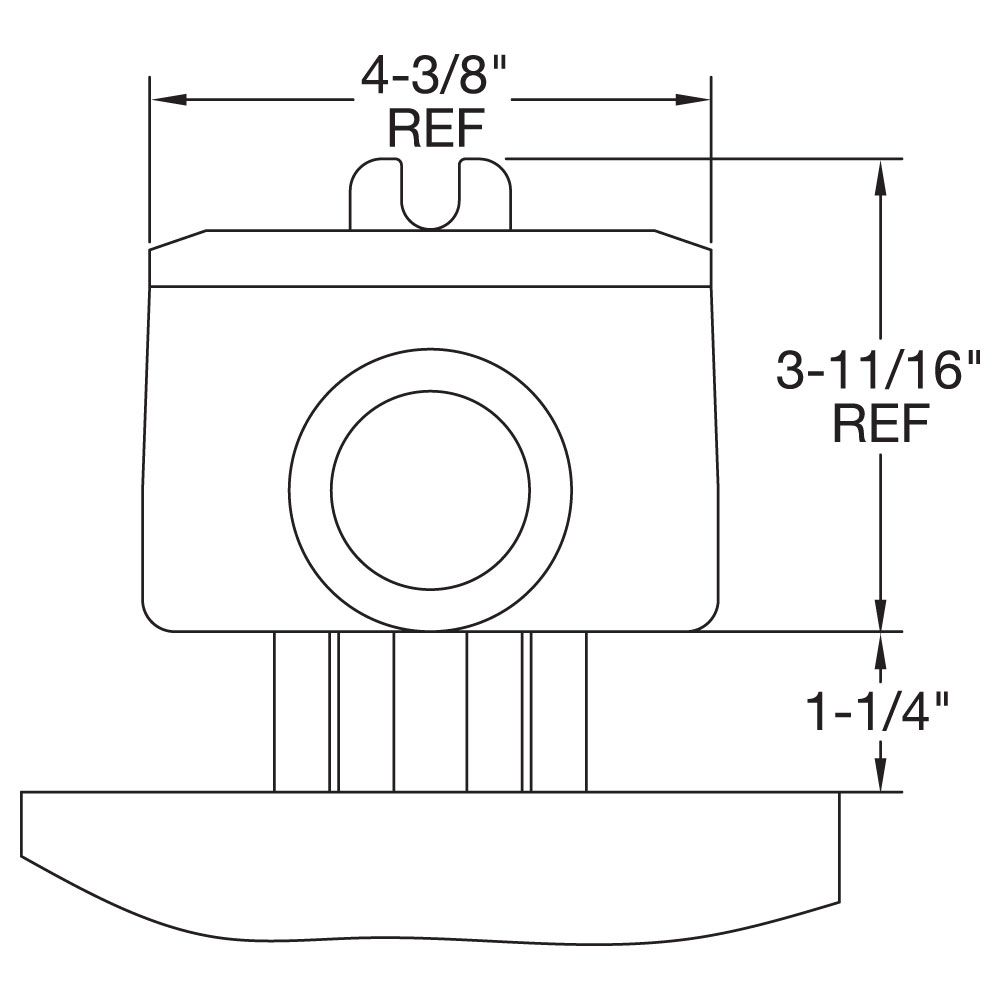

Type MPR: Moisture Resistant Box

This design has a moisture resistant die cast aluminum box with a non-removable polyurethane gasket in the lid. Lid is secured with captive stainless steel screws. Body and lid are painted in basic industrial gray; interior contains copper ground screw. Box is mounted to a plate that is brazed to the element. Available in a wide variety of sizes.

Type MPR: Moisture Resistant Box

This design has a moisture resistant die cast aluminum box with a non-removable polyurethane gasket in the lid. Lid is secured with captive stainless steel screws. Body and lid are painted in basic industrial gray; interior contains copper ground screw. Box is mounted to a plate that is brazed to the element. Available in a wide variety of sizes.

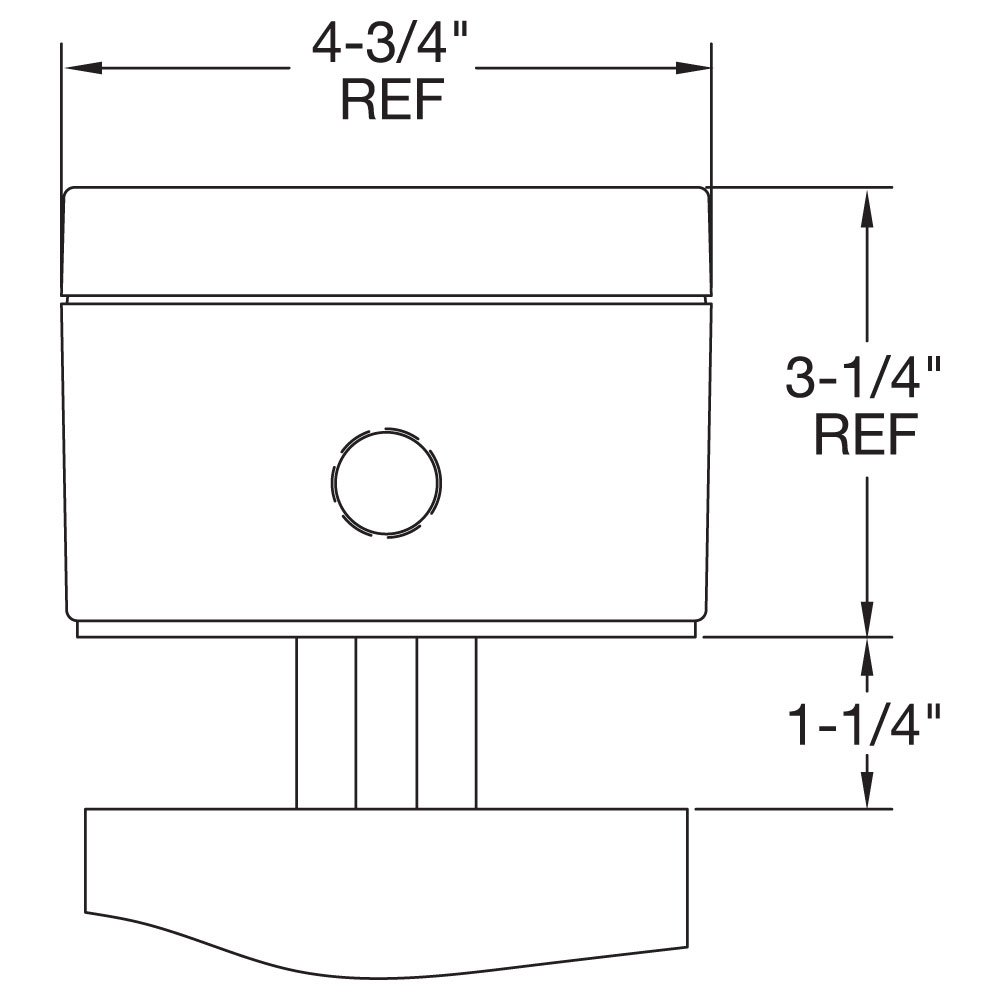

Type MR1: Moisture Resistant Box with Shield

This design incorporates the MPR housing style along with a perforated tube shielding unheated extensions of the tubular heating elements. This feature provides mechanical strength to the element extension and prevents overheating of the terminals, reducing possible premature failure from corrosion and oxidation.

Type MR1: Moisture Resistant Box with Shield

This design incorporates the MPR housing style along with a perforated tube shielding unheated extensions of the tubular heating elements. This feature provides mechanical strength to the element extension and prevents overheating of the terminals, reducing possible premature failure from corrosion and oxidation.

Additional Options

No options available for this section based on your selections

125 RMS Standard

RMS Surface Finish as defined in ASME B46.1 — RMS is the root mean square of the profile height deviations from the mean line, recorded within the evaluation length. The standard surface finish for the machined surface of Tempco cast-in heaters is 125 RMS. Consult Tempco if a different surface finish is required.

125 RMS Standard

RMS Surface Finish as defined in ASME B46.1 — RMS is the root mean square of the profile height deviations from the mean line, recorded within the evaluation length. The standard surface finish for the machined surface of Tempco cast-in heaters is 125 RMS. Consult Tempco if a different surface finish is required.

Special Features

Electroless Nickel-Plated — A plating technique (without using an electric current) used to deposit a coating of nickel on a substrate to prevent corrosion, wear and also as a protective coating.

Teflon Coating — Teflon is non-reactive so it is often used in containers and pipework for reactive and corrosive chemicals.

Hard coat anodizing — Anodizing increases resistance to corrosion and wear.

Magnaplate — Strong wear and corrosion resistance non-stick coating that withstands high temperatures.

Special Features

Electroless Nickel-Plated — A plating technique (without using an electric current) used to deposit a coating of nickel on a substrate to prevent corrosion, wear and also as a protective coating.

Teflon Coating — Teflon is non-reactive so it is often used in containers and pipework for reactive and corrosive chemicals.

Hard coat anodizing — Anodizing increases resistance to corrosion and wear.

Magnaplate — Strong wear and corrosion resistance non-stick coating that withstands high temperatures.