Click or tap image to expand

Over-the-Side Immersion Heaters (OTS)

Over-the-Side Immersion Heaters General Purpose Over-the-Side Immersion Heaters, Vertical Loop Low-Profile Immersion Heaters, Sanitzing Sink Immersion Heaters and Deep Tank/Sump Immersion Heaters are manufactured with Incoloy®, Stainless Steel, Steel or Copper heating elements and NEMA 4 Terminal Housings. Additional construction details include:

- power leads for the elements travel up through a riser pipe and are connected to a terminal block inside the housing

- heaters are wired for three-phase unless otherwise specified

- optional thermostat

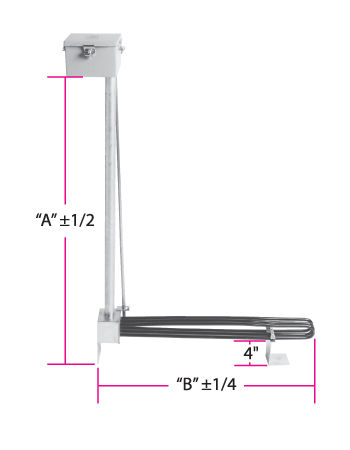

General Purpose Immersion Heaters

Design Features

- Lightweight and Portable

- Easy Installation and Removal

- 304 or 316 Stainless Steel construction for all wetted parts

- Passivation of all wetted parts – electropolished or bright annealed surface treatments for Stainless Steel or Incoloy designs (heating elements only)

- NEMA 1 or NEMA 4/7 (explosion resistant) terminal housings

- Flange, fixed or adjustable bracket on riser for mounting

- Mounting flange for terminal housing

- External power wiring options include flexible cord/plug, armored cable, wire braided or plain lead wire

- Double- or Single- pole thermostat (see catalog page 11-6 for available ranges)

- Process or Hi-limit thermocouple in thermowell in place of the thermostat

- Hi-limit MI thermocouple on sheath

- Special riser and/or sludge leg heights

- Up to 12 elements per heater assembly

- Right-angle riser design

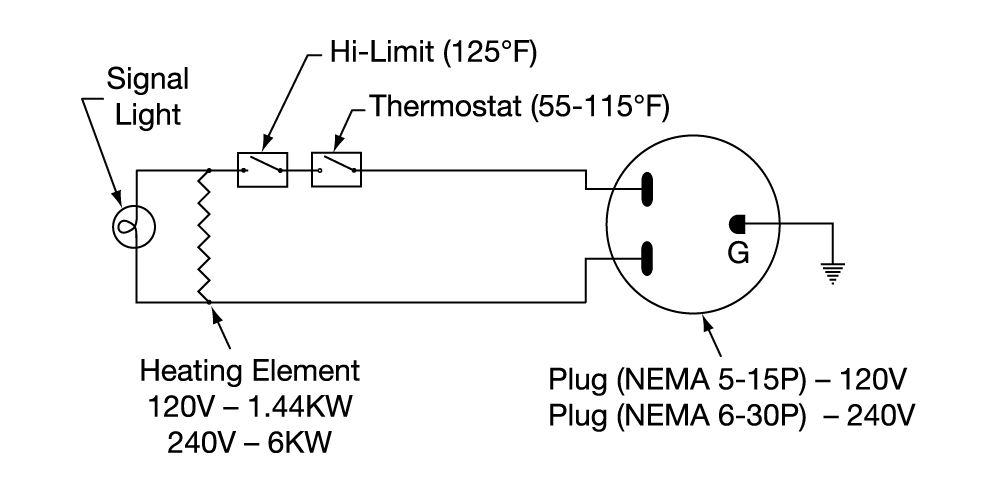

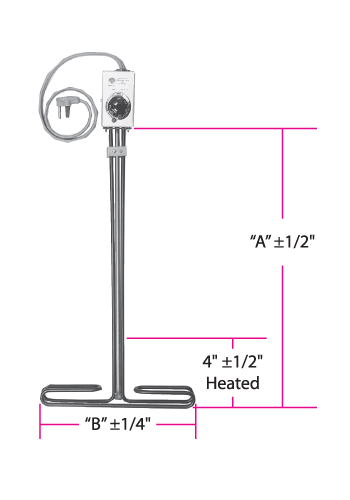

General Purpose Tank or Reservoir

Water Immersion Heaters

Design Features

- Immersion section of heater made of 316 Stainless Steel

- Cold riser extends to the top of container where control housing is located

- Cord set with 3-wire grounding plug is included for easy installation and wiring

- Adjustable vapor-proof thermostat control with temperature range of 55°F to 115°F (±3°)

- Hi-limit cut switch set to 125°F (±4°)

- Stainless Steel mounting bracket also supplied for easy mounting

- Pilot light and on-off switch provided

Hazard of electric shock. Installation must be grounded to earth and heater connected to line input through properly sized GFCI circuit breaker.

Disconnect power to heater before servicing. There should be no body contact with the water while the heater is in the water.

Under NO circumstances should this heater be turned on unless the system is full of water.

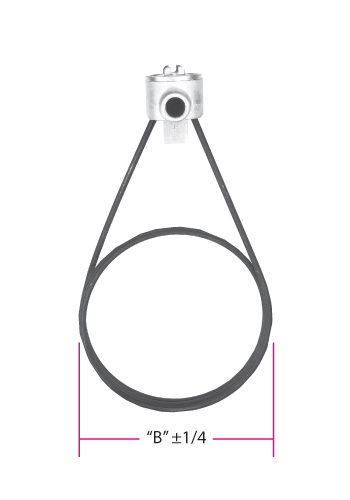

Vertical Loop – Low-Profile Immersion Heaters

Design Features

- Used on open-top tanks for heating water, water-based solutions, citrus juices, plating tanks, oil tempering, salt baths and other mild corrosive solutions

- NEMA 4 (moisture resistant) housing with integral grounding terminal is standard. Other NEMA ratings available

- Low-profile design with adjustable SS mounting bracket

- Optional Passivated, Electropolished, or Bright Annealed surface treatments available for Stainless Steel or Incoloy sheath designs

- External power wiring options including flexible cord/plug, armor cable, braided or plain lead wire

- Optional Hi-limit MI thermocouple on heater sheath

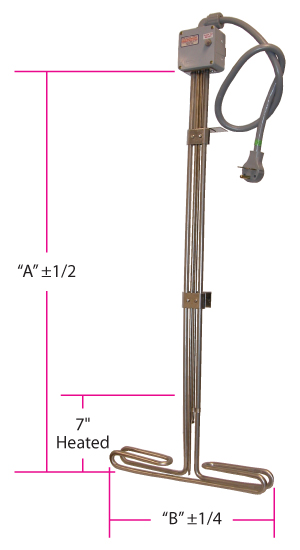

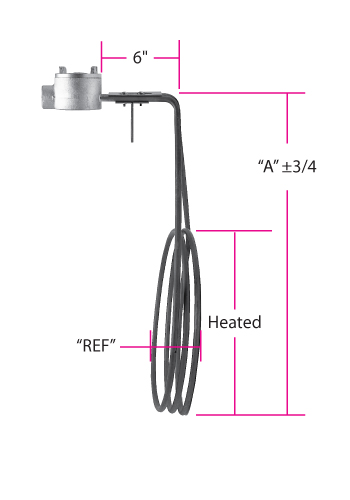

Sanitizing Sink Immersion Heaters

Design Features

- Used for sterilization of water tanks in restaurants, taverns and laboratories

- Double Pole 60-250°F thermostat with over-temperature cutout. Optional pilot lamp to indicate heater on/off status available

- Standard 6 ft. (optional 4 ft.) cord set with grounding plug (NEMA 5-15P for 120V and 6-30P for 240V)

- Adjustable Stainless Steel mounting bracket

- Consult Tempco for custom designs

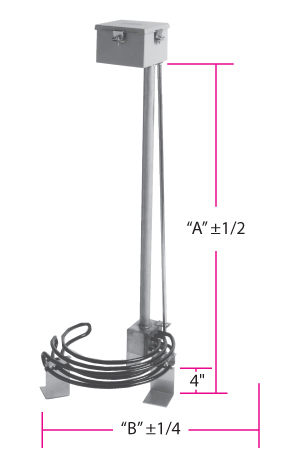

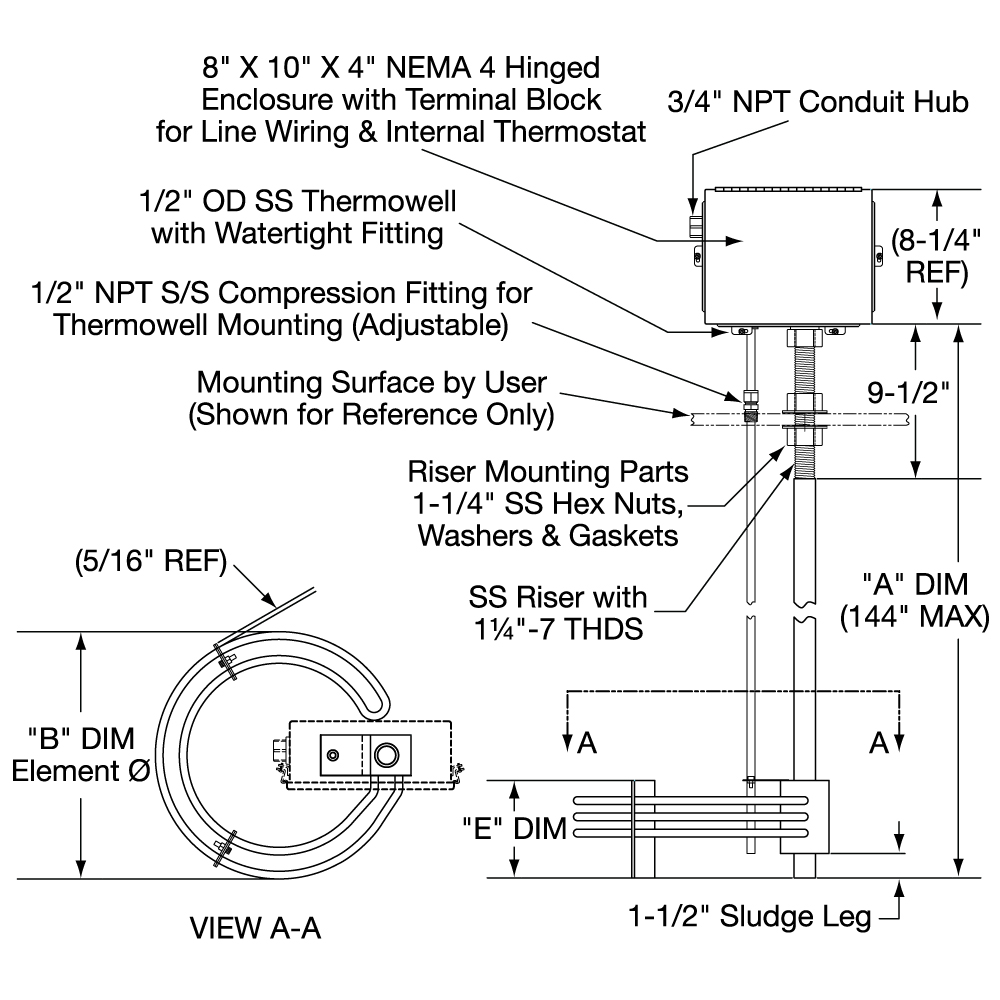

Deep Tank/Sump Immersion Heaters

Design Features

- .475 diameter Incoloy elements and stainless steel wetted parts standard

- Designed for permanent installation in outdoor/indoor applications

- 2 ft to 12 ft vertical riser height (for thermostat designs)

- Weathertight mounting hardware supplied

- Riser adjustable to facilitate mounting variations

- NEMA 4 Electrical Enclosure with 3/4 conduit fitting

- 1-1/2″ Sludge legs

- Double-pole 60-250°F pilot duty thermostat

- Watertight thermowell sized for 3/8″ max. dia. sensing bulb

Optional Features

- 316 SS, Steel, or Copper element designs

- Passivation, electropolished, or bright annealed surface treatments for stainless steel or Incoloy designs (elements only)

- Custom or ASI pressure rated flange on riser for mounting

- NEMA 1 or NEMA 4/7 (explosion resistant) terminal housings

- Alternate single- or double-pole thermostat (see page 11-6 through 11-9 for ranges)

- Internally mounted definite purpose Magnetic Contactor, single circuit units only (see page 13-96 for volt/amp ratings and coil voltages available)

- RTD or Process MI thermocouple in thermowell in place of thermostat

- Hi-limit thermocouple on element sheath

- Special riser or sludge leg heights

- Right-angle riser design for offset terminal housing

- Up to 24 elements per heater assembly

- 1/32 DIN temperature controller, internal or panel mounted on terminal housing and used with T/C or RTD probe & contactor for heater control

- Integrated float switch for liquid level control