Case Study

Precision in Motion: Inside Tempco’s Forced Air In-line Heaters

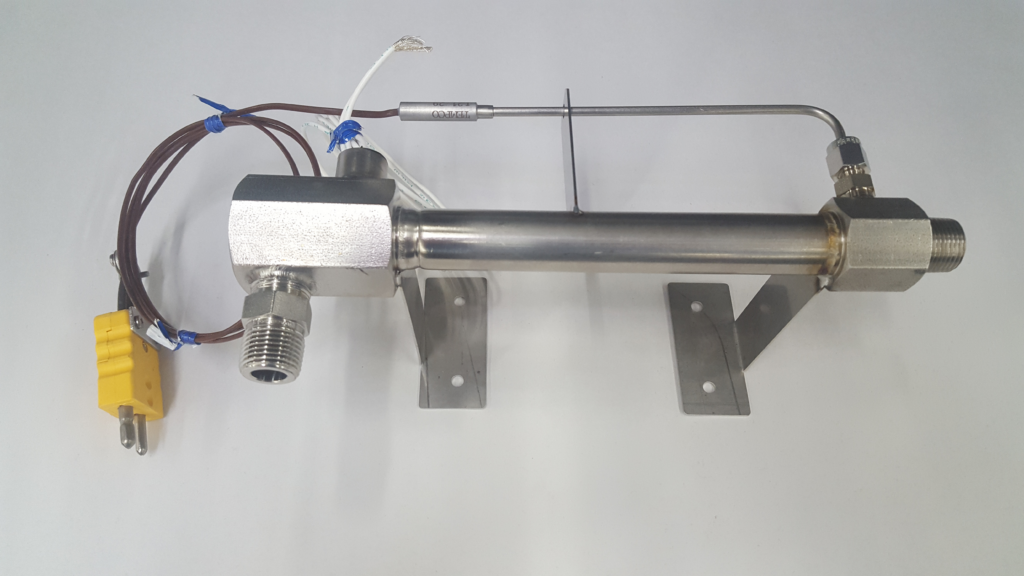

In industries where precision and consistency mean everything, the ability to control heat in motion can make or break a process. Whether its sealing packages on production lines, melting materials without burning them, or preheating gases for pressurized systems, Tempco’s Forced Air In-line Heaters provide a reliable and focused source of heat built for movement, not contact.

How Forced Air In-line Heaters Work

Forced air in-line heaters operate by drawing air or gas through an inlet and heating it along internal coils as it travels to the outlet. The concept seems simple: air in, heat applied, air out. The engineering? Anything but basic. Inside each unit, precisely wound coils transfer energy as the air flows across them, gradually increasing the temperature along the length of the heater until it exits at the desired level. Every design is tailored to be capable of operating in the customer’s environment.

Tempco offers two designs for these in-line heaters: Low Temperature (LDA) and High Temperature (HAC). The difference between them lies mainly in internal construction and performance range. LDA heaters use coils running through ceramic insulators while HAC heaters feature a coil wound around a specialty core.

Real-World Applications

Forced air in-line heaters operate by drawing air or gas through an inlet and heating it along internal coils as it travels to the outlet. The concept seems simple: air in, heat applied, air out. The engineering? Anything but basic. Inside each unit, precisely wound coils transfer energy as the air flows across them, gradually increasing the temperature along the length of the heater until it exits at the desired level. Every design is tailored to be capable of operating in the customer’s environment.

Tempco offers two designs for these in-line heaters: Low Temperature (LDA) and High Temperature (HAC). The difference between them lies mainly in internal construction and performance range. LDA heaters use coils running through ceramic insulators while HAC heaters feature a coil wound around a specialty core.

Designed for Performance, Built for Reliability

Tempco’s commitment to quality begins long before testing, though. Every project starts with understanding the customer’s application, from temperature goals and airflow to spatial constraints and pressure conditions. If the heater is expected to run continuously at high temperatures, Tempco engineers often recommend a specific model, like the HAC, for improved longevity. For pressurized systems above 3-4 PSI, a sealed design is used to prevent leaks, while non-pressurized designs use a cost-effective fitting.

Every in-line heater that leaves Tempco’s facility undergoes rigorous testing and quality checks. During production, each unit can be pressure-tested, typically to 100 PSI, before reaching final quality control.

Precision Control Through Smart Engineering

A key advantage of Tempco’s in-line heater design is its compatibility with accurate temperature monitoring and control systems. Beyond the heater itself, Tempco also makes and sells a full range of temperature measurement and control components, including thermocouples, RTDs, temperature controllers, power control panels, and sensors, engineered to work seamlessly with their heaters. This integrated ecosystem ensures tighter control, faster response, and optimal heater performance in demanding industrial environments.

Maintaining proper airflow is another critical factor. Too little airflow? The coils overheat, deform, or fail. Too much? The air never hits target temperature. Achieving the balance between flow and heat is part of Tempco’s engineering process, and it’s why every custom part is tailored to the customer’s specific needs.

Know Your Application

Want the best performance? Start with communication. Providing complete application information, including target temperatures, spatial limitations, air or gas pressure, and operational patterns, helps Tempco’s design team ensure that every heater is built to last in its specific environment. These factors enable engineers to use Tempco’s derived formulas to achieve the targeted temperatures.

“Sometimes customers ask for a specific heater, but after we review their setup, we’ll suggest a different design that performs better,” explains Stan, one of Tempco’s design engineers. “We don’t just want to sell a heater; we want to provide the right solution for their process.” This collaborative approach has been part of Tempco’s identity since its founding. Tempco engineers want to ensure their products are both reliable and long-lasting.

The Unseen Backbone of Modern Heating

Forced air in-line heaters may not draw attention like some other heating technologies like radiant panels, immersion heaters, or cast-in heaters but they fill a vital niche: focused, controlled heat in motion. By combining precise coil engineering, thermocouple feedback, and robust quality assurance, Tempco’s in-line heaters continue to power countless industrial systems where reliability is not optional. Behind every unit is a team dedicated to precision and performance. From first design drawing to final inspection, every heater carries the same promise: dependable heat, consistent performance, American craftsmanship.

Need a custom heating solution? Tempco’s team has decades of experience designing parts that last. Contact Tempco to find the right fit for your application.