When the going gets tough, the enclosure heaters get going.

Enclosure heaters are a critical first line of defense for outdoor electronic equipment that is exposed to harsh winter elements. The heaters, which sit inside boxes or cabinets that house circuitry, can be programmed to power up when temperatures fall below a specific threshold or remain on around the clock to carefully control the climate inside.

Outdoor devices that we rely on every day, from traffic lights to cell towers, contain sensitive components that depend on proper climate control. Without it, temperature fluctuations and excess moisture could lead to short circuiting, component failure, and other problems that knock them offline. And when that happens, the cost of the disruption to a business or the public at large will often far outweigh the modest investment that could have avoided it.

Why Enclosure Heaters?

In places like New England, the Great Lakes Region and the Pacific Northwest, outdoor electrical and electronic equipment is at risk to cold threats for the majority of the year. Frigid conditions can cause condensation and frost to form inside enclosures when humid air cools rapidly, leading to the degradation of metal parts, oxidation of contacts, and ice buildup that interferes with moving components.

Even in warmer or variable environments, high humidity or rain intrusion can create a damp environment that accelerates rusting and increases the risk of electrical shorts. Temperature swings between hot days and cool nights can cause the expansion and contraction of air, drawing moisture into the enclosure and stressing seals, gaskets, and sensitive electronics.

An enclosure heater mitigates these risks by maintaining a stable, slightly elevated internal temperature. This prevents moisture from gathering on surfaces, keeps electronics within their optimal operating range, and ensures that lubricants or mechanical parts do not freeze. In combination with proper ventilation or thermostatic controls, enclosure heaters create a controlled microclimate that shields equipment from the damaging effects of weather.

Any upfront costs for enclosure heaters can be made up many times over through the lower energy use, fewer repairs, and prolonged equipment performance they bring.

Major Users

Enclosure heaters play a crucial role in ensuring uninterrupted operations and safety for many industries. Over the last 20 years, their prominence has grown along with the explosion of wireless communication technologies and our needs for infrastructure to accommodate them, such as telecom cabinets and antennae arrays. Industries that rely on the protection provided by enclosure heaters include:

- Energy & Utilities: Power distribution panels, wind turbines, and solar inverter enclosures use heaters to protect electronics from moisture and temperature swings.

- Oil, Gas & Petrochemical: Heaters safeguard instrumentation, monitoring, and safety systems in harsh outdoor or offshore environments.

- Marine & Ports: Protects sensitive equipment in coastal areas where salt air and humidity accelerate corrosion.

- Food & Beverage Processing: Control enclosures in cold storage or washdown areas benefit from heaters to prevent condensation damage.

Tempco Solutions

Enclosure heaters typically use convection, conduction, or radiant heating to maintain a stable internal environment. They are available in a variety of forms, depending on the application’s size, required heat output, and operating conditions.

Tempco offers four distinct styles of enclosure heaters designed to protect electrical and electronic equipment:

- Ceramic (E-mitter) Heaters (EHC): Utilize a Ceramic E-mitter (infrared bulb) housed in a NEMA-1 box with a perforated stainless-steel guard. They are a top choice for applications that require radiant heating.

- Finned Strip Heaters (EHF): Feature a stainless-steel sheath with fins and T4 screw terminals, easily mounted in enclosures for efficient heat distribution. Outstanding for generating broad, even heating.

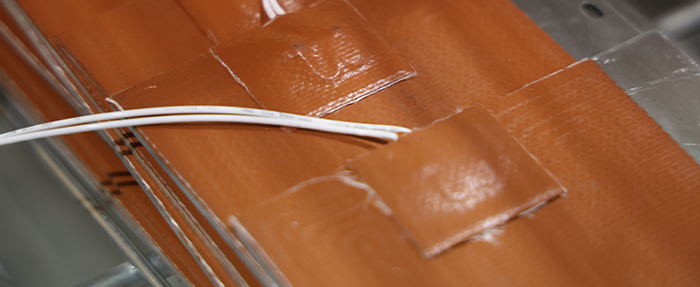

- Silicone Rubber Heaters (EHR): Wire-wound silicone rubber elements vulcanized to an aluminum plate, providing easy installation and great protection against freezing and humidity. Ideal for compact, moisture-prone enclosures.

- Tubular Heaters (EHT): Come in box or open styles using Incoloy® tubular elements, capable of high watt density. An excellent selection for heavy-duty, high-wattage needs.

Case closed: Tempco Is Your Heating Answer

If you’re considering an enclosure heater for an application, we recommend contacting a Tempco expert to discuss which options would be the right fit for your needs. Tempco has a world-class engineering staff and state-of-the-art facilities to customize heating equipment to accommodate any need you may have. You can also count on our team to prepare a prompt quote to assist with your decision.

Download our Enclosure Heater Catalog to learn more about the Tempco solutions designed specially for your industry.