When a food packaging company known for its innovative and sustainable processing reached out to us, they had a clear challenge: they needed a flange immersion heater for a water-processing application at their heating plant. However, not any standard water heater would work, certain criteria needed to be fulfilled, including:

- 20,000 litre water capacity

- Water temperature of 65° C

- Corrosion resistance to handle chlorinated town water

Letting the ideas flow

From the start, we kept communication open and feedback flowing. As the customer shared their requirements, our engineering team refined the design to meet their heating and wiring needs while also making sure installation would be as straightforward as possible. After multiple rounds of back-and-forth communication, we knew exactly what would best fit our customer’s needs.

The Final Result?

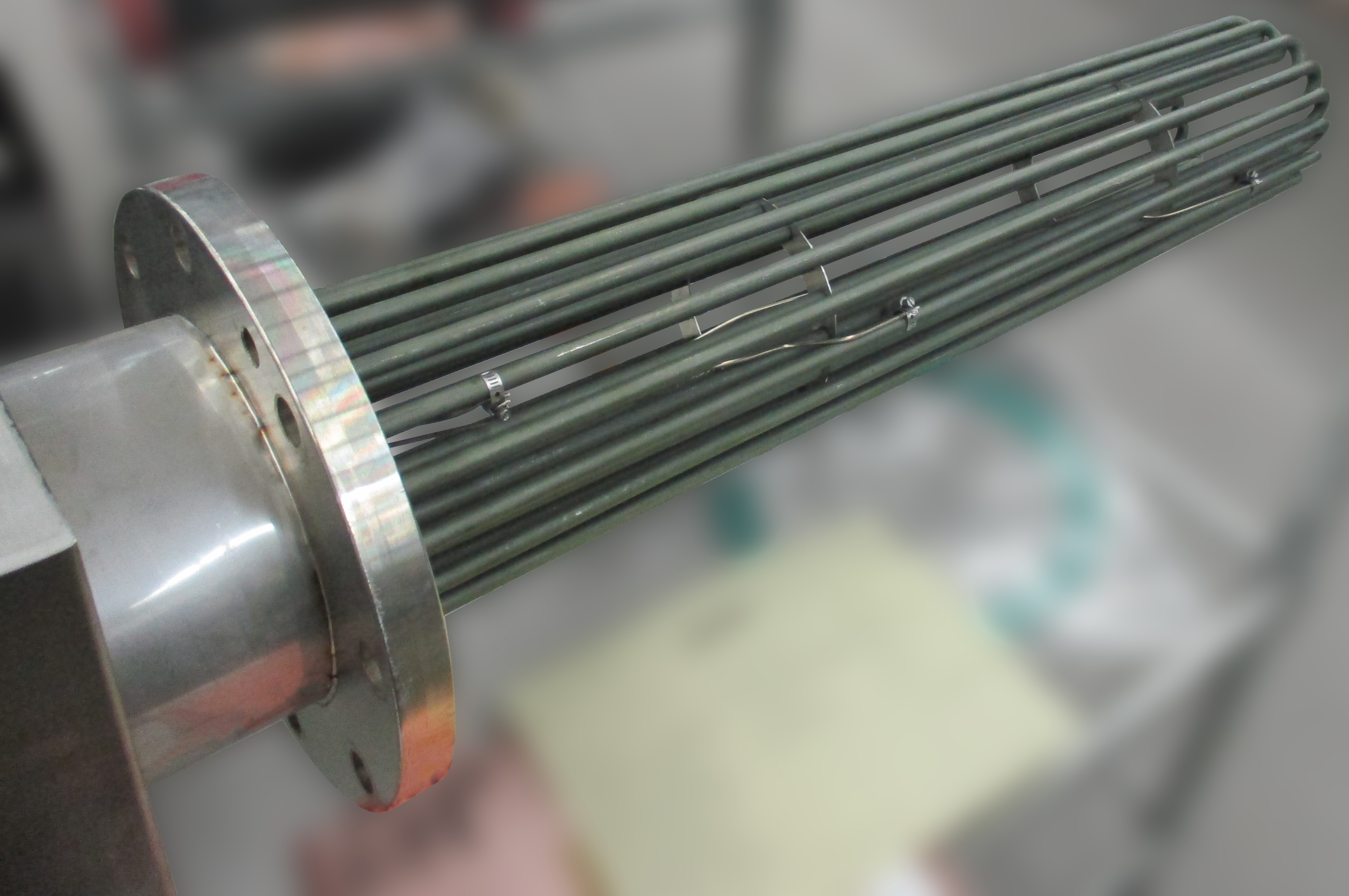

A custom, large flange immersion heater built to handle the job. Here’s what we delivered:

- A heater with an overall length of approximately 50 inches

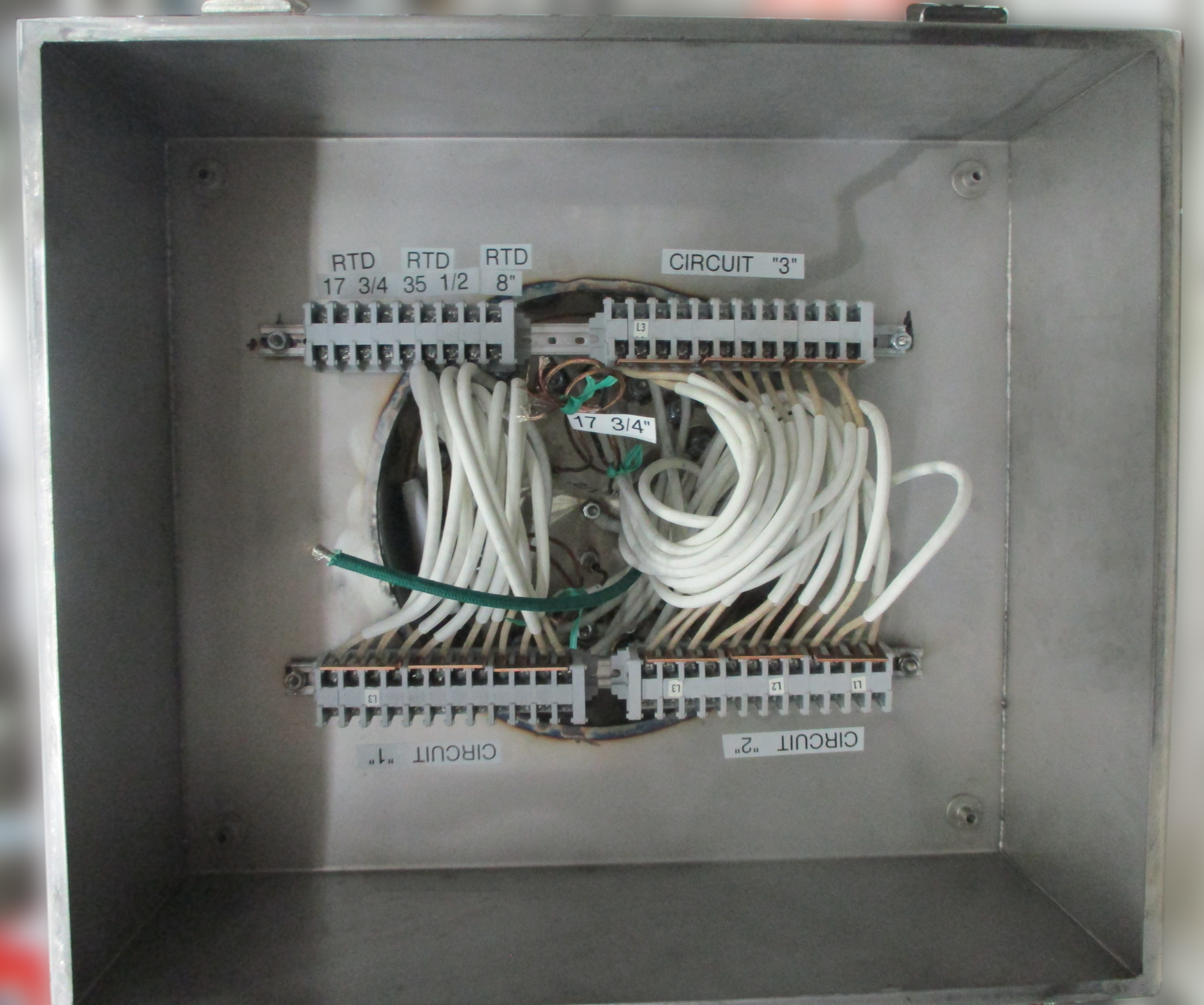

- A rugged 316 Stainless Steel NEMA 4 terminal housing, measuring 16 in. x 14 in. x 6 in.

- 18 Incoloy® heating elements, capable of producing a total of 80 KW of heat

- Elements individually wired into three circuits, using terminal distributions blocks mounted on DIN rails inside the terminal housing

- Three RTD temperature sensors extending to three different lengths on the immersed section of the heater to monitor water temperature.

One standout feature of this design is its operational resilience. Because each element is individually wired and the RTDs measure temperature at multiple levels, the heater can continue running as needed even if one element stops functioning.

Lessons Learned

This project showed us that with clear communication and thoughtful engineering, even large-scale heating challenges can be solved efficiently and reliably, something we’ve seen time and time again. By staying closely aligned with the customer from day one, we were able to deliver a high-performance solution to meet their demanding daily operations, and do so with built-in durability and serviceability. In total, the duration of the project, from quoting, to designing, to manufacturing, was less than 13 weeks.

If you have a problem that needs a custom heating solution, Tempco’s team has decades of experience designing parts that last. Contact Tempco to find the right fit for your application.